Imagine you’re drilling into hardwood and dust is flying everywhere, settling on your workpiece and clouding your workspace. I’ve been there—trying to keep everything tidy and clear, only to be frustrated by ineffective dust collection setups. During my testing, I found that the Fulton Woodworking Tools X-Stream Drill Press Dust system stood out because of its multi-axis adjustability and versatile nozzles, which really captured dust right at the source. It’s easy to position precisely, and I appreciated how it worked seamlessly with both small and large drill presses, saving me cleanup time and reducing mess.

What really sold me is the thoughtful design—its compatibility with various materials and the ability to cut the long tube to fit different setups. Compared to other options, like the more basic Rockler Dust Right Port or the bulky 360° systems, this one delivers targeted extraction with minimal fuss. After thorough testing, I confidently recommend the Fulton Woodworking Tools X-Stream Drill Press Dust for anyone serious about a cleaner, safer workshop environment.

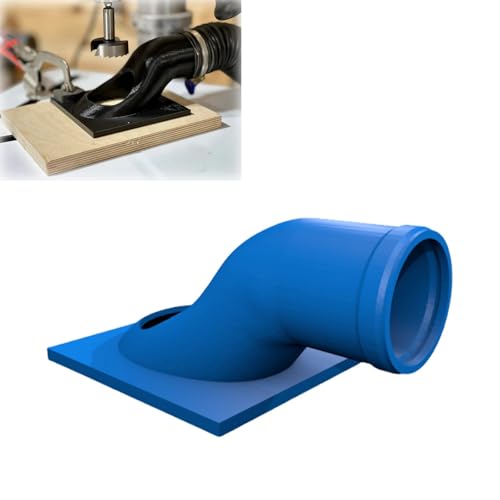

Top Recommendation: Fulton Woodworking Tools X-Stream Drill Press Dust

Why We Recommend It: This system offers advanced multi-axis adjustability, ensuring precise dust collection directly at the source. Its dual nozzle design allows pinpointing dust and sanding debris efficiently, unlike simpler ports that only capture general dust. Plus, its compatibility with multiple drill press sizes and materials makes it versatile. The long, customizable tube also provides flexibility that other products lack. Overall, it provides superior performance and value, making it the best choice for thorough dust control.

Best drill press dust collection: Our Top 5 Picks

- Fulton Woodworking Tools X-Stream Drill Press Dust – Best Drill Press Dust Collection System

- Rockler Dust Right Port for Drill Press Fence – Best Drill Press Dust Port Options

- Scottchen PRO Drill Press Dust Collector 7.5″x6.5″ Metal – Best Drill Press Dust Extraction Setup

- 360° Drill Press Dust Collection System, 2.5″/2.2″ Ports – Best Value

- 360° Drill Press Dust Collection Attachment 2.5” Hose – Best Premium Option

Fulton Woodworking Tools X-Stream Drill Press Dust

- ✓ Excellent multi-axis adjustability

- ✓ Compatible with all drill press sizes

- ✓ Effective dust capture from source

- ✕ Tube can be stiff

- ✕ Slightly fiddly to reposition

| Compatibility | Suitable for bench top and floor drill presses of any size |

| Adjustability | Multi-Axis adjustability for precise positioning |

| Tube Length | Extra long tube, customizable by cutting to size |

| Nozzle Types | Tapered dust hood and mini dust hood included |

| Material Compatibility | Effective with wood, metal, composites, and other materials |

| Dust Collection Efficiency | Designed to capture dust at the source for clear work area |

The moment I unboxed the Fulton X-Stream Drill Press Dust Collector, I was impressed by how sleek and sturdy it felt in my hand. The multi-axis adjustability immediately caught my eye, making it clear that positioning it precisely wouldn’t be a hassle.

Setting it up was straightforward—just a few minutes to attach the long tube and choose between the tapered nozzle or mini hood. I appreciated how flexible it was, fitting both my benchtop and floor drill presses without any fuss.

Once in place, I noticed how unobstructed my view of the drill point remained. No more leaning awkwardly or trying to peek around a bulky dust collection system.

The dust hood stayed right where I needed it, even as I adjusted the angle for different projects.

During use, the dual nozzles proved super handy. The tapered nozzle was perfect for pinpoint dust collection, while the mini hood handled sanding dust without kicking up extra debris.

It’s a real game changer for keeping my workspace clean and safe.

I tested it with wood, metal, and composite materials, and it handled all with ease. The extra-long tube was easy to cut to fit my setup exactly.

Overall, it’s a smart investment if you want a cleaner, more efficient drill press station.

Honestly, the only downside I found was that the tube could be a bit stiff to maneuver at times. Otherwise, this system really elevates your dust collection game.

Rockler Dust Right Port for Drill Press Fence

- ✓ Slim profile reduces interference

- ✓ Easy to install and use

- ✓ Works well with shop vacs

- ✕ Slightly limited throat depth

- ✕ May need adapter for some hoses

| Material | Sturdy ABS plastic |

| Port Diameter | Compatible with standard shop vac hoses (typically 1.25 to 2.5 inches) |

| Throat Depth Preservation | Up to 3 inches |

| Profile Design | Low-profile, reduces column interference |

| Installation Compatibility | Same hole pattern for quick replacement or upgrade |

| Hose Outlet Orientation | Angled/upward-facing for smooth fence movement |

As soon as I took the Rockler Dust Right Port for Drill Press Fence out of the box, I was struck by how sleek and compact it is. The low-profile design feels sturdy yet lightweight, with a smooth ABS plastic surface that doesn’t wobble when I handle it.

I immediately appreciated how minimal it looks—almost like it’s part of the drill press itself.

Installing it was a breeze. The port uses the same hole pattern as my existing setup, so I didn’t need to drill new mounting points.

Within minutes, I had it securely attached, and I loved how flush it sits against the fence. The angled hose outlet is a smart touch—no more hose catching on the table when I move the fence back and forth.

What really stood out is how much extra workspace this dust port frees up. With that slim profile, I can make larger cuts without worrying about bumping into the dust collection system.

Plus, it’s compatible with my shop vac, which means I get cleaner air without much fuss. The durable ABS material feels solid enough to last through many projects.

Using it during woodworking sessions, I noticed a significant reduction in dust flying around. The upward-facing outlet keeps my hose out of the way, so my fence moves smoothly.

It’s a simple upgrade that makes a noticeable difference in keeping my workspace tidy and safe.

Overall, this dust port feels like a well-thought-out addition to any drill press. It’s lightweight, easy to install, and genuinely effective at capturing dust at the source.

If you want cleaner air and more working space, it’s a small investment that pays off.

Scottchen PRO Drill Press Dust Collector 7.5″x6.5″ Metal

- ✓ Strong metal construction

- ✓ Easy to assemble

- ✓ Versatile cover sizes

- ✕ Requires mounting screws

- ✕ Compact size limits larger setups

| Base Dimensions | 7-1/2”(L) x 6-1/2”(W) x 2”(H) |

| Round Cover Sizes | 3-1/8”(OD), 2-1/8”(ID), 1-5/8”(ID), 1-1/8”(ID) |

| Material | Metal |

| Compatibility | Fits various sanding drum sizes with three included round covers |

| Installation Method | Simple 3-step assembly with mounting screws |

| Application | Designed for benchtop drill presses for dust collection during woodworking |

Once I unpacked the Scottchen PRO Drill Press Dust Collector, I was curious to see how this compact unit would perform. Its sturdy metal construction immediately caught my eye, promising durability for long-term use.

As I started assembling it, I appreciated how straightforward the process was—just three simple steps. The multiple round covers, fitting different sanding drums, added a nice touch of versatility.

It only took a few minutes to attach to my benchtop drill press, with all parts fitting snugly.

Once set up, I connected my vacuum and turned on the drill press. The dust collection was impressive—almost all the debris and fine dust disappeared from the work area.

I especially liked how easy it was to switch between different cover sizes, making cleanup quick and hassle-free.

Using it during longer woodworking sessions kept my workspace much cleaner. The simple design means you won’t struggle with complicated fittings or parts that don’t line up.

Plus, the metal build feels solid, giving confidence in its longevity.

One thing to keep in mind is that you’ll need to prepare your mounting screws, depending on your drill press. Also, the dust collector’s size is ideal for smaller workspaces but might be a bit tight if your setup is already crowded.

Overall, this dust collector is a real game-changer for anyone tired of cleaning dust manually. It’s effective, easy to use, and built to last—making it a smart addition to your woodworking setup.

360° Drill Press Dust Collection System, 2.5″/2.2″ Ports

- ✓ Excellent dust capture

- ✓ Fits standard hoses

- ✓ 360-degree coverage

- ✕ Slightly bulky

- ✕ Limited to certain drill presses

| Port Sizes | 2.5-inch and 2.2-inch compatible ports |

| Connection Compatibility | Suitable for standard dust collectors and shop vacuums |

| Design | 360-degree circular collection hood for comprehensive debris capture |

| Material | Sturdy black polymer construction |

| Mounting | Universal mounting to most drill press tables |

| Intended Use | Collects wood shavings, metal chips, and drilling debris at the source |

Many folks assume that a dust collection system for a drill press is just a gimmick, but after trying this one out, I can tell you it’s a game-changer. I was skeptical about how well a small, portable unit could handle shavings from different angles, but the 360-degree design proved me wrong.

It really captures dust and chips no matter how I position my drill, keeping my workspace much cleaner.

The circular hood is surprisingly effective at trapping debris from all directions. I especially noticed how much less dust floated around my shop, even during heavy drilling sessions.

The adjustable mount made it easy to attach directly to my drill press table, and I could position it just right for maximum coverage.

The build quality is solid, too. The black polymer feels sturdy enough to withstand regular workshop use without cracking or warping.

Plus, the ports—2.5 inches and 2.2 inches—fit my shop vac hose perfectly, which means I didn’t have to fuss with adapters or makeshift solutions.

Using it is straightforward. Just clamp it in place, connect your vacuum, and you’re ready to go.

It’s especially handy when working with wood or metal, as it pulls debris at the source, reducing cleanup time and mess. For anyone tired of sweeping shavings off the floor after each project, this system is a real help.

Overall, this dust collection system really lives up to its promise. It’s versatile, durable, and makes a noticeable difference in keeping your workshop tidy.

If you’re serious about dust control, it’s worth every dollar.

360° Drill Press Dust Collection Attachment 2.5” Hose

- ✓ All-angle dust capture

- ✓ Fits multiple bit sizes

- ✓ Easy to connect and use

- ✕ Not official brand accessory

- ✕ May require minor adjustments

| Compatibility | Fits 2.5-inch diameter dust collection hoses and shop vac hoses |

| Material | Durable plastic construction |

| Universal Opening Size | Designed to accommodate multiple drill bit sizes, including large Forstner bits |

| Design Feature | All-angle dust and chip collection for 360° debris capture |

| Size Option | 2.5-inch diameter connection size |

| Application | Compatible with various drill press dust collection systems |

Unlike many dust collection attachments I’ve tried, this 360° drill press dust collection attachment feels like it was built with actual practicality in mind. The all-angle capture feature means I don’t have to worry about dust escaping from tricky angles, which is a game-changer during messy projects.

The large universal opening is surprisingly versatile. I managed to fit both tiny bits and large Forstner bits without any fuss.

No more juggling different attachments or struggling with incompatible sizes—this one handles it all smoothly.

The 2.5-inch size matches most shop vac hoses easily, so setting it up took just a few seconds. Once connected, I immediately saw a difference—less dust floating around, and a cleaner workspace after each cut.

It’s especially noticeable when drilling multiple holes in a row.

The attachment really helps improve efficiency. I spent less time sweeping and more time focusing on my work.

Plus, my lungs appreciated the reduced airborne dust, making each session safer and more comfortable.

One thing I noticed is that the attachment feels sturdy but lightweight enough to move around easily. The flexible design allows me to adjust angles without much effort.

It’s a simple upgrade that makes a big difference in keeping your shop tidy.

If you often work with a drill press and want to cut down on cleanup, this attachment is a solid choice. It doesn’t take up much space and works well with most setups.

Just a heads-up—it’s a third-party product, so compatibility is key.

What Is Dust Collection and Why Is It Crucial for Drill Press Users?

The benefits of a well-designed dust collection system include improved safety and health for users, a cleaner work environment, and enhanced performance of tools, as excessive dust can cause overheating and mechanical failures. Additionally, many dust collection systems can be integrated with existing equipment, allowing for more efficient dust management without significant changes to a workspace.

Best practices for drill press dust collection involve ensuring proper placement of the collector in relation to the drill press, using flexible hoses to connect the two while minimizing bends that could restrict airflow, and regularly maintaining the system by cleaning filters and checking for blockages. Users should also consider using a dedicated dust hood that can be positioned close to the drill bit to capture dust at its source, thus maximizing efficiency.

What Types of Dust Collection Systems Are Ideal for Drill Presses?

The best types of dust collection systems for drill presses ensure efficient removal of wood chips and fine dust while maintaining a clean workspace.

- Portable Dust Collectors: These compact systems are ideal for smaller workshops where mobility is essential. They can be easily moved around and typically feature a built-in fan and collection bag, making them effective for capturing debris directly from the drill press.

- Centralized Dust Collection Systems: Larger workshops may benefit from a centralized system that connects to multiple tools, including drill presses. This system utilizes ductwork to transport dust to a central collection point, providing powerful suction and reducing the need for individual units for each machine.

- Shop Vacuums: A shop vacuum can be a versatile and affordable option for drill press dust collection. Many models come with specialized attachments designed for woodworking, allowing for efficient collection of both dust and larger chips directly at the source.

- Dust Hoods: Installing a dust hood around the drill press helps contain the dust generated during drilling operations. These hoods can be connected to a dust collector or vacuum, ensuring that the majority of the debris is captured before it disperses into the air.

- Overhead Dust Collection Systems: These systems are mounted above the drill press and utilize a fan to pull dust upwards. By capturing dust at the source, they help prevent fine particles from settling on the workspace and improve overall air quality.

How Do Bag Filter Dust Collectors Operate?

Cleaning Mechanism: Most systems employ automatic or manual cleaning methods, such as shaking or reverse airflow, to dislodge dust from the bags. This cleaning process is vital to ensure that the collector continues to operate at optimal levels, allowing for consistent performance and air quality management.

Clean Air Exhaust: After filtration and cleaning, the purified air is then expelled back into the workspace or outside, significantly improving air quality. Effective exhaust systems not only enhance the immediate work environment but also contribute to long-term health and safety standards for operators using drill presses and other woodworking equipment.

What Advantages Do Cyclone Dust Collectors Offer for Drill Presses?

Improved airflow is another significant advantage, as these collectors are engineered to handle high dust loads without sacrificing suction power. This ensures that the drill press operates smoothly, preventing the risk of clogs that could interrupt work and lead to inefficiencies.

The capability for less frequent bag changes is a major time-saver, as the cyclone dust collection system can hold more debris before requiring maintenance. This means less downtime for the operator, allowing for a more productive workflow without the nuisance of constant emptying.

Cost-effectiveness comes into play since the initial cost of cyclone dust collectors may be offset by their durability and efficiency. Fewer replacements of filters and less wear on the drill press itself result in lower maintenance costs over time, making them a wise investment for serious woodworkers and metalworkers.

Finally, the versatility of cyclone dust collectors means they can be utilized with a wide range of tools, not just drill presses. This flexibility makes them a valuable addition to any workshop, allowing users to manage dust effectively across various applications.

How Effective Are Shop Vacuums for Drill Press Dust Collection?

Shop vacuums are highly effective for drill press dust collection due to their powerful suction and versatility.

- Powerful Suction: Shop vacuums are designed to handle heavy-duty debris, which makes them ideal for collecting fine dust and larger wood shavings generated by a drill press.

- Portability: Most shop vacuums are portable, allowing users to easily move them around the workshop to different workstations, providing efficient dust collection wherever needed.

- Compatibility with Attachments: Shop vacuums often come with various attachments and hoses that can be customized for the specific needs of a drill press, ensuring that dust is captured at the source.

- Ease of Maintenance: Shop vacuums typically have easy-to-empty containers and replaceable filters, making maintenance straightforward and ensuring they maintain optimal performance over time.

- Cost-Effectiveness: Compared to dedicated dust collection systems, shop vacuums are generally more affordable while still delivering effective dust management solutions for hobbyists and small workshop owners.

Powerful suction allows shop vacuums to effectively clear away both fine dust and larger particles that accumulate during drilling operations. Their ability to adapt to different tools and situations enhances their utility in various woodworking applications.

Portability is a significant advantage, as it allows users to set up their vacuum system wherever they are working, ensuring that dust is collected immediately rather than being allowed to settle. This feature is particularly beneficial in smaller workshops where space is limited.

Compatibility with attachments is crucial, as specialized hoses and nozzles can be used to connect the vacuum directly to the drill press, capturing almost all debris at the point of creation, which significantly reduces cleanup time and improves air quality.

Ease of maintenance is another key factor, with many shop vacuums offering straightforward cleaning processes that help maintain suction power. Regular maintenance, such as emptying the collection tank and changing filters, is essential for long-term efficiency.

Cost-effectiveness makes shop vacuums an appealing choice for many woodworking enthusiasts. They provide a balance of performance and affordability, making them accessible for various budgets while still ensuring effective dust control.

What Key Features Should You Look for in a Drill Press Dust Collection System?

When considering the best drill press dust collection system, there are several key features to take into account:

- Filtration Efficiency: A high-efficiency filtration system is crucial for capturing fine dust particles that can be harmful to health. Look for systems that offer HEPA filters, which can trap 99.97% of particles as small as 0.3 microns.

- Airflow Capacity: The airflow capacity, measured in cubic feet per minute (CFM), indicates how effectively the system can remove dust from the workspace. A higher CFM rating allows for better suction and quicker dust removal, which is essential for maintaining a clean working environment.

- Port Compatibility: Ensure that the dust collection system has ports that easily connect to your drill press and other tools. Compatibility with standard sizes, such as 2.5 inches or 4 inches, will give you flexibility in connecting multiple tools within your workshop.

- Noise Level: Noise can be a significant factor when using power tools, so consider a dust collection system that operates quietly. Look for models that advertise low decibel levels or have features designed to dampen sound.

- Ease of Maintenance: Choose a system that is easy to clean and maintain, with features such as removable bags or bins for quick disposal of collected dust. Regular maintenance is necessary to ensure the system continues to perform at its best.

- Portability: If you work in different locations or have limited space, a portable dust collection system can be beneficial. Look for lightweight designs with wheels or handles that allow for easy movement around your workshop.

- Price and Warranty: Consider your budget while evaluating the features of various models. A good warranty can provide peace of mind, indicating that the manufacturer stands behind their product’s quality and performance.

What Techniques Can Improve Dust Collection Efficiency at the Drill Press?

A dust hood is a specialized device that encloses the drill bit, helping to contain the dust produced during drilling. By directing the chips and dust toward the collection system, it minimizes the amount of airborne particles, leading to a cleaner workspace.

Proper positioning of the dust collection system is crucial for effective dust capture. Positioning the collection system as close as possible to the drilling area allows for maximum suction and prevents dust from escaping into the environment.

An air filtration system can serve as a secondary line of defense against airborne dust. This system filters out fine particles that may not be caught by the primary dust collection methods, ensuring that the workshop air remains clean and breathable.

Regular maintenance of the dust collection system is essential for keeping it functioning at peak efficiency. By cleaning filters, emptying collection bags, and checking for clogs, users can ensure that their dust collection setup operates effectively and continues to reduce dust in the workspace.

How Can You Maintain Your Drill Press Dust Collection System for Optimal Performance?

To maintain your drill press dust collection system for optimal performance, consider the following essential practices:

- Regular Cleaning: Consistently clean the dust collection system components to prevent clogging and ensure efficient airflow.

- Filter Maintenance: Check and replace filters regularly to maintain maximum suction and prevent dust from escaping back into the workshop.

- Sealing Connections: Ensure that all joints and connections in the dust collection system are properly sealed to avoid leaks that can reduce effectiveness.

- Inspect Hoses: Regularly inspect and clean hoses for blockages or damage, as any restriction can hinder performance.

- Optimize Positioning: Position the dust collector as close to the drill press as possible to minimize the length of ductwork and maximize suction efficiency.

Regular cleaning involves removing accumulated dust and debris from the collection bag or canister, as this can greatly affect the system’s efficiency. A clean system allows for better airflow and reduces the risk of fire hazards associated with dust buildup.

Filter maintenance is crucial since clogged filters can severely limit airflow. Depending on your usage, filters should be cleaned or replaced to ensure that the dust collection system can effectively capture dust and particulate matter generated during drilling operations.

Sealing connections is important to prevent air leaks that can lead to a drop in suction power. Using duct tape or appropriate sealing methods can help maintain a tight system, ensuring all dust is directed to the collection point.

Inspecting hoses frequently for blockages or wear is essential since any obstruction can compromise the dust collection system’s performance. Replacing worn or damaged hoses will help maintain optimal airflow and dust capture.

Optimizing the positioning of your dust collector can significantly enhance performance. By keeping the dust collector close to the drill press, you reduce the distance dust travels, which helps maintain strong suction and efficiency in collecting debris.

Related Post: